Semi-production machining of cast iron pulleys on Okuma LS lathe. Bore precision machined to +0.001″ / -0.000″

Category Archives: Uncategorized

Fixture Component Machining

Fixture plates, v blocks and locating pins. Machined, ground and bored complete in-house on Excello milling machine, Okuma LS lathe, J&S cylindrical grinder and Moore jig borer.

Aluminum Clamp Block Machining

Al 6061-T6 blocks machined complete on Excello milling machine. Precision bored on Moore Jig Borer.

Delrin Flange Bushings

Reverse engineered from customer sample. Delrin flange bushings with o-ring grooves turned on Okuma LS lathe.

Maintenance and Repair

RBL Machinery offers maintenance and repair services. We can fix (sleeve) shafts, bushings, flanges, brackets, or other parts or can reverse engineer to make new. Can accommodate shafts upto 60″ long. Contact us to inquire how we can help.

Cast Iron Bracket Machining

Semi-production machined and slotted cast iron brackets for local foundry. Completed on Excello 602 milling machine.

UHMW Bushing Machining on Excello Mill

Machined on custom fixture manufactured in-house. 3 operations for a complete part.

Side Grinding on Jones & Shipman

A2 tool steel side grinding of gage surfaces on Jones & Shipman cylindrical grinder. Tolerance within .001″

Stainless Steel Shaft Repair

Repair of stainless steel auger on Okuma LS lathe. Bearing diameters sleeved and re-machined to .0004″ tolerance for agricultural machine.

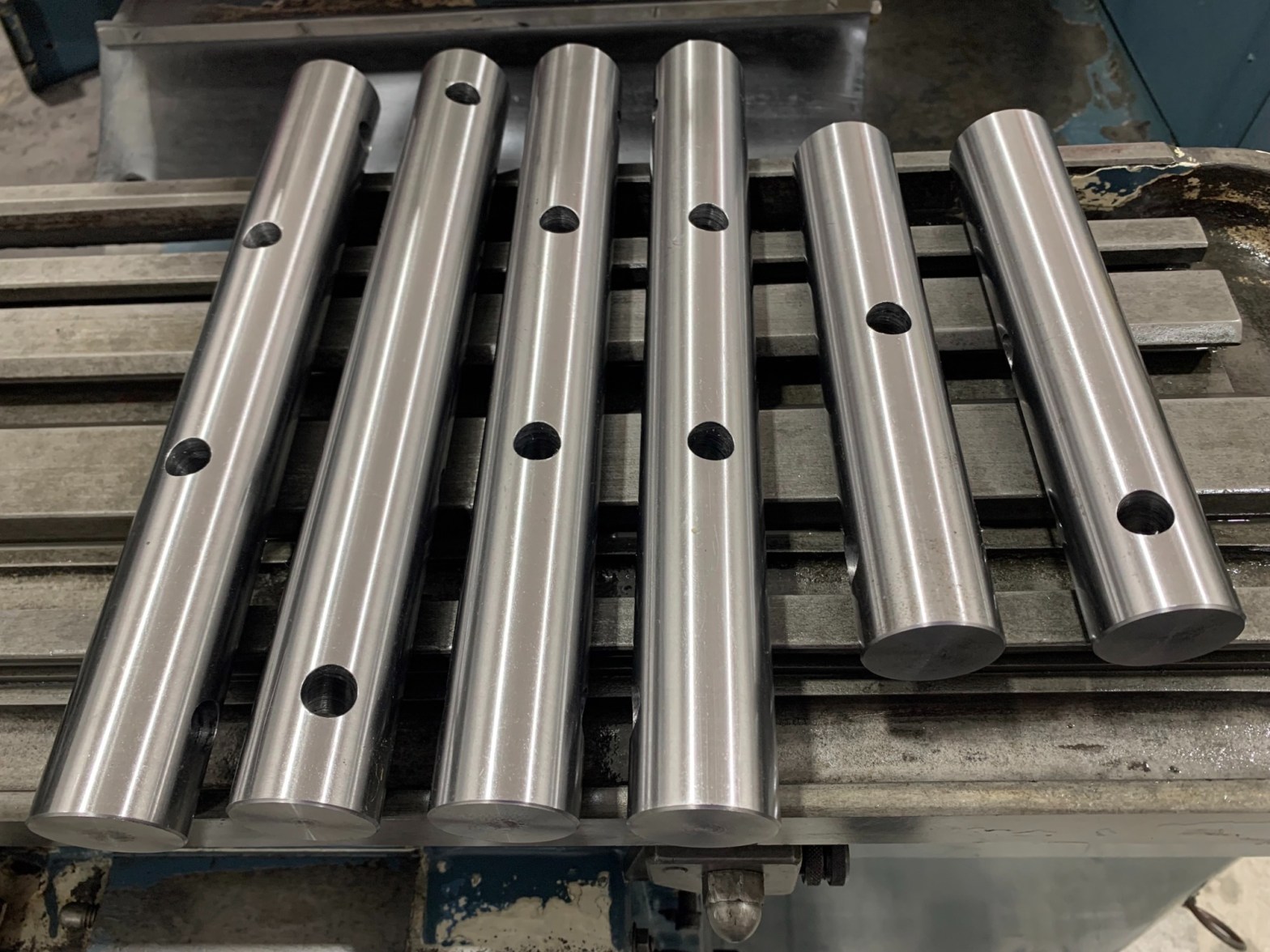

1045 Precision Shaft Machining

Precision ground SAE 1045 machined joiner shafts for a local customer. Cross drilled 90° for mounting. Machined in-house using Okuma lathe, Excello mill and Jones & Shipman universal grinder.